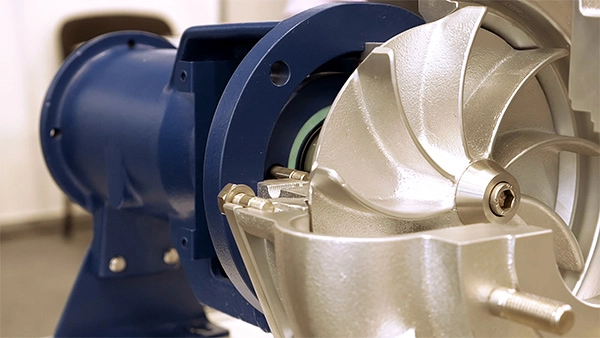

When the hydraulic pump is in use, due to some reasons, the pressure at a local position in the pump drops to the saturated vapor pressure of water at the corresponding temperature, and the water begins to vaporize and generate a large number of bubbles. Then, what harm do bubbles do to the hydraulic pump? The following is an explanation:

1. The source of bubbles in the oil and their harm to the hydraulic pump;

(1) The source of bubbles

① Hydraulic oil is produced, stored and transported, and the system works under atmospheric pressure, so it is inevitable that the oil contains air. Air in the oil is often called mixed air. Mixed air is a spherical bubble with a very small diameter suspended in the oil. There are two ways to generate mixed air:

② It is mainly mixed into the oil through the oil tank and the suction pipe of the pump. If the oil level in the oil tank is too low and the pump suction pipe is half exposed above the oil surface, air can be sucked in. If the pump’s oil inlet pipeline leaks, a large amount of air will be sucked in. If the system return oil pipe outlet is higher than the oil level in the oil tank, the high-speed jetted system return oil rolls up the air into the oil and is brought into the system again through the oil pump.

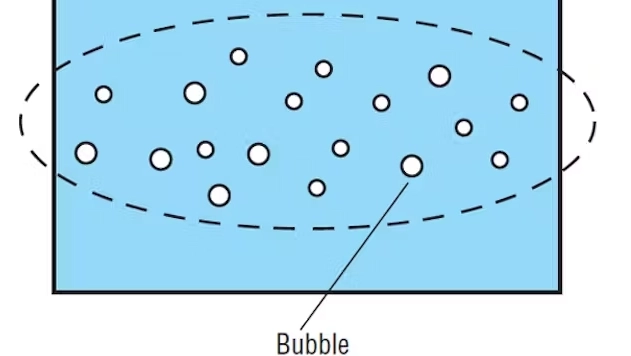

③ Although practice has proved that the air dissolved in the oil has no direct effect on the physical properties of the oil, when the oil that has dissolved a certain amount of air and is in a saturated state flows through the throttle or pump inlet section, when the absolute pressure drops to the air separation pressure of the oil, the supersaturated air in the oil will be precipitated, causing the fine bubbles originally dissolved in the oil to gather into larger bubbles that appear in the system.

2. The harm of bubbles to the system From the perspective of economy and system working quality, bubbles in oil are very harmful to the system, mainly in the following aspects:

(1) Poor system operation. In the hydraulic transmission system, oil is the power transmission medium. In the absence of air mixing, its compression rate is about (5~7)x10-10m3/N, that is, when the pressure increases by 10MPa, the volume is only compressed to 0.625%. Therefore, in general hydraulic pumps, oil can be considered as a non-compressible fluid without considering its compressibility. Once air is mixed into the oil, its compression rate will increase significantly, and the oil itself has a relatively high stiffness or a large volume elastic coefficient (the inverse of the compression rate), which will be greatly reduced, seriously endangering the working reliability of the system, such as automatic control failure, intermittent motion of the working mechanism, and increased scrap rate of the processed parts. Mechanical and personal accidents may also occur due to device malfunction caused by bubbles.

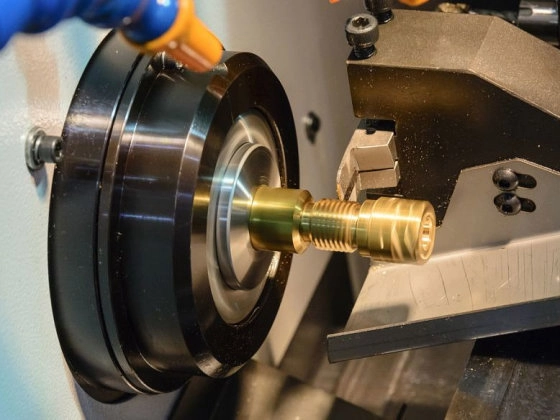

(2) Increased oil temperature. After the instantaneous compression of bubbles in pumps, their temperature will rise sharply. If the gas does not dissolve in the oil, the approximate value of the temperature rise due to its adiabatic shrinkage is not difficult to calculate. For example, when the 35℃ air bubble is pressurized to 3.5MPa, its temperature rise can reach 580℃. After the air bubble reaches a high temperature, the oil around it will burn, which becomes the main reason for the sudden increase in the system oil temperature. However, air is difficult to conduct heat. When there are bubbles in the oil, its thermal conductivity is greatly reduced, which seriously affects the cooling effect of the oil.

3. The adverse consequences of increased oil temperature include the following main aspects:

(1) Accelerated oil oxidation. Increased oil temperature is the main reason for promoting oil oxidation. According to the oxidation mechanism, when the oil temperature is above 60°C, the oxidation rate doubles for every 10°C increase. Oxidized oil usually increases viscosity and generates acidic compounds, causing corrosion of metal parts in the system. In addition, the chemical properties of oxides are generally more active than the products of pyrolysis, so it is easier to produce sludge, together with mechanical impurities such as rust and metal chips, which act as catalysts in the oxidation process and accelerate the oxidation of oil. It is generally hoped that the oil temperature can be below 90°C to give it good chemical stability.

(2) The lubricating properties of the oil decrease. Oil with good performance can form a strong oil film on the metal friction surface. The strength and thickness of the oil film mainly depend on the quality of the oil. The oil film strength of the deteriorated oil is not enough to withstand the pressure of the workload, causing the metal surfaces to contact each other, resulting in a sharp increase in friction and accelerated wear of parts. Therefore, the lubricity of the oil is of great significance to hydraulic devices.

(3) Accelerate the aging of seals. The seals used in hydraulic pumps are made of materials with different chemical compositions, such as various forms of sealing rings and gaskets. They are not only required to have good compatibility with the oil, but also to have an appropriate working oil temperature. If the oil temperature exceeds the normal heat-resistant temperature of the seal, it will accelerate the aging of the seal, lose its proper elasticity, and cause the premature loss of sealing performance.

(4) Cause cavitation. When the bubbles in the oil are brought to the high-pressure area by the oil, the volume shrinks sharply, and the bubbles condense into liquid again, forming a vacuum in the rear area. The surrounding liquid particles fill this space at high speed. The particles collide with each other to generate local high pressure, forming a hydraulic shock, which can increase the local pressure by hundreds or even thousands of atmospheric pressures. If this local hydraulic shock acts on the solid wall, it can cause erosion of the solid wall, which is called cavitation, which is very harmful to the system. Bubbles in the oil can also cause adverse effects such as increased vibration and noise of the system and reduced volumetric efficiency of the pump.