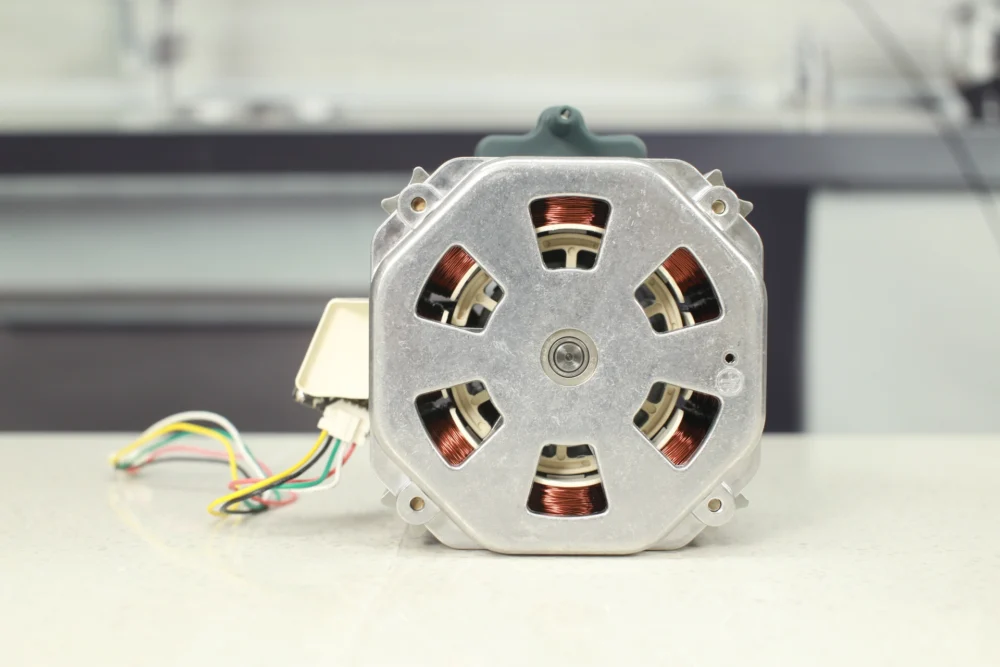

1. Use servo motor to directly drive the main oil pump of hydraulic press to achieve energy saving.

At present, there are still many difficulties in directly driving hydraulic pump with high-power servo motor, mainly requiring the speed range of hydraulic pump to be very large. The minimum speed of general hydraulic pump is 600 r/min, and hydraulic pump can work normally even below 10 r/min.

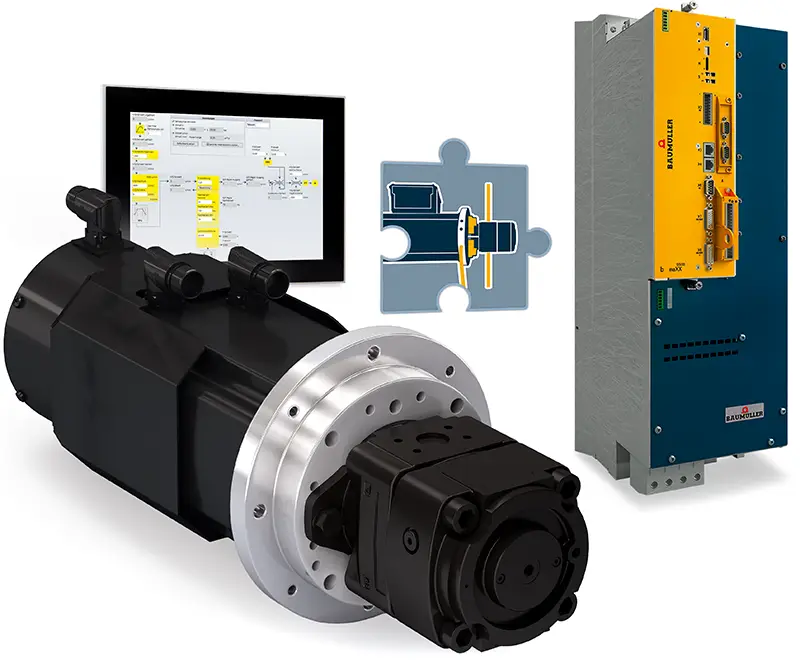

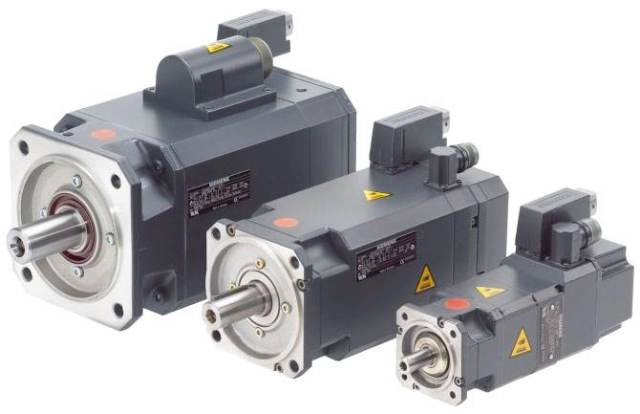

High-power AC servo motor and its control technology The emergence of high-power AC servo motor is a new product produced in the past 10 years. At present, the main technology used is the switched reluctance motor (SMR), which has the advantages of simplicity and reliability, high efficiency in a wide range of speed and torque, four-quadrant operation, fast response speed and low cost. Its disadvantages are: large torque fluctuations and large vibrations; the system has nonlinear characteristics, high control costs, and low power density.

The AC servo motor drive control unit is composed of large-scale integrated circuits, high-power rectifier modules and other electronic power components. With the development of electronic technology, the performance of high-power AC servo motor drive control units has been continuously improved, and the price has been continuously reduced, which has promoted the realization and promotion of high-power AC servo drive technology and provided the possibility for the use of AC servo drive in the field of forging equipment. The research focus is to concentrate scientific research forces to develop high-power AC servo motor control technology and related application technologies with independent intellectual property rights, and provide a solid foundation for the development of servo hydraulic presses.

2. Closed-loop control of hydraulic pressure and position is achieved by changing the speed of the servo motor.

The closed-loop control technology of hydraulic pressure and position of hydraulic press by servo motor is not mature. Traditional hydraulic presses control hydraulic pressure and position through proportional valves and proportional servo valves. It is necessary to study special control algorithms to make the hydraulic pressure have high stability and high precision between 1 and 25 MPa.

3. Research on energy recovery and energy management system.

In order to save more energy and minimize energy loss, it is necessary to recycle the potential energy of the slider’s own weight and the energy generated by the cylinder’s pressure relief. At present, there is no mature practice and experience in this regard. In terms of energy management, since the instantaneous power is many times greater than the average power, energy allocation should be done well in large servo hydraulic presses to avoid impact on the power grid.

4. Research and development of special control systems.

Most existing hydraulic presses are controlled by PLC, but servo hydraulic presses use hydraulic and speed closed-loop program control, which requires a large amount of calculations, so ordinary PLCs are difficult to meet the needs. The control system of the servo hydraulic press is controlled by industrial PC, so a special control system must be developed.

5. Forming process optimization based on servo hydraulic press.

The materials and shapes of each stamping part are different, resulting in completely different stamping processes. For example, in the silent blanking process, the control of the speed change point is the key; in the reverse extrusion forming of magnesium alloy cup-shaped parts, the slider needs to experience 4 different speeds in one working cycle, and the extrusion process is still under constant pressure control. Therefore, the servo hydraulic press can only play its superiority when combined with various forming process optimizations. It is very important to study the forming mechanism of various forming processes and establish the optimization parameters suitable for the forming process to improve product quality and production efficiency and reduce production costs.

6. Optimized design of servo hydraulic press body.

Compared with traditional hydraulic presses, servo hydraulic presses have advantages such as energy saving and noise reduction, so their body design needs to consider more factors, mainly including various possible extreme working conditions, working frequency, complexity of stamping parts, etc. For a long time, domestic engineering and technical personnel have mainly used empirical methods and similar product analogy methods for design. Domestic forging machine products have shortcomings such as large size, heavy weight, and poor control accuracy. Steel consumption is one of the key factors in product cost control for forging machine manufacturers.