On the industrial stage, the hydraulic press is like a silent but powerful giant. Although it is not often in the spotlight, it quietly promotes the development of many industries behind the scenes. Today, let us unveil the mysterious veil of the hydraulic press!

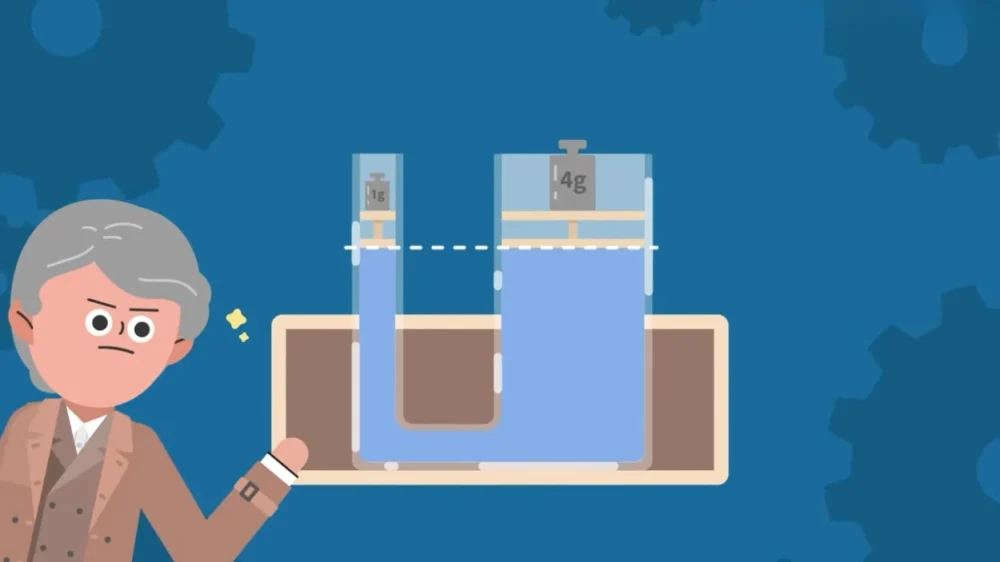

1. The wonderful application of Pascal’s law

The working principle of hydraulic presses is based on the famous Pascal’s law. In simple terms, in a closed hydraulic system, the pressure applied to the liquid can be transmitted to all parts of the liquid and the walls of the container without changing its size. It is like using two syringes, one large and one small, connected by a short tube. When the large syringe is pressed hard, the liquid is transferred to the small syringe, and it is much easier to squeeze the liquid back from the small syringe. If you put a book on the large syringe and push it with the small syringe, the book will obviously rise; but if you turn it upside down and push the small syringe with the large syringe, the book will move very little or even not move. This is the magic of hydraulic presses that can generate high pressure with small force.

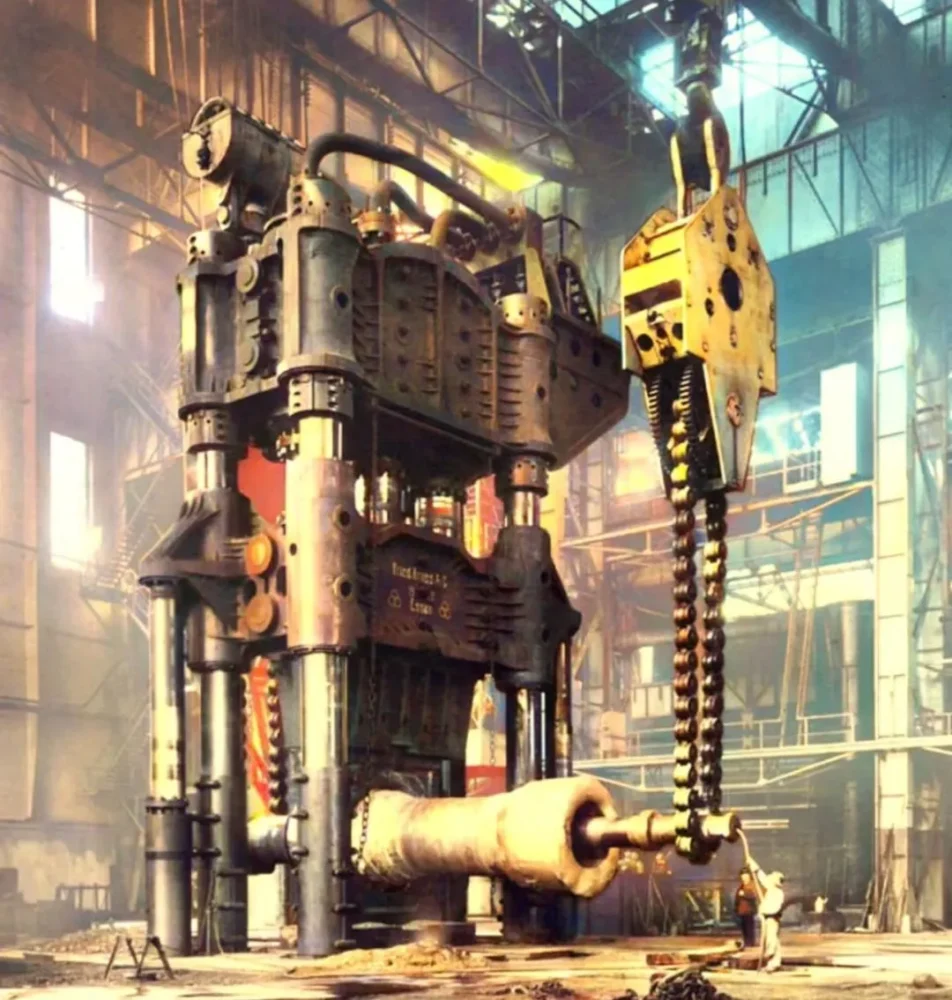

2. A powerful assistant for industrial production

Hydraulic presses are widely used in industrial production and life. In heavy industries such as shipbuilding, forging containers, and the chemical industry, it is an indispensable key equipment. Due to its strong pressure, it is also used in production procedures such as calibration, pressing, and packaging. Someone once did an experiment and put a hair dryer under a hydraulic press, which was instantly flattened, showing its strong pressure. Even on the Internet, there are short videos of using hydraulic presses to press candies, donuts and other snacks to relieve stress. Watching the snacks being pressed into uniform strips is amazing.

3.Advantages and disadvantages coexist

The advantages of hydraulic press are significant. It can generate huge pressure and complete various high-intensity work tasks. Moreover, the working process is relatively stable and can ensure processing accuracy. However, it also has some disadvantages. Hydraulic presses are usually large in size and consist of three parts: the machine (main machine), the power system and the hydraulic control system. Once a fault occurs, it is difficult to troubleshoot. Common problems such as heating and unstable operation require one-by-one inspection of multiple components such as hydraulic cylinders, hydraulic pumps, hydraulic valves, and hydraulic systems; when oil leakage occurs, it is also necessary to check the damage of seals, oil contamination, whether the pressure is too high, and whether there are any abnormalities at the leakage point. Therefore, many companies are equipped with special maintenance personnel to regularly maintain hydraulic presses to ensure their normal operation.