This paper introduces the specific composition and working principle of aircraft hydraulic systems, reviews the development history of civil aircraft hydraulic systems, and looks forward to the development trend of civil aircraft hydraulic systems. In response to the needs of future civil aircraft development, some new key technologies for civil aircraft hydraulic system research are proposed, including distributed technology, lightweight technology, intelligent technology, etc., and are introduced in detail. The review of the development history of civil aircraft hydraulic systems and the outlook for future trends provide technical support for the development of domestic civil aircraft hydraulic systems.

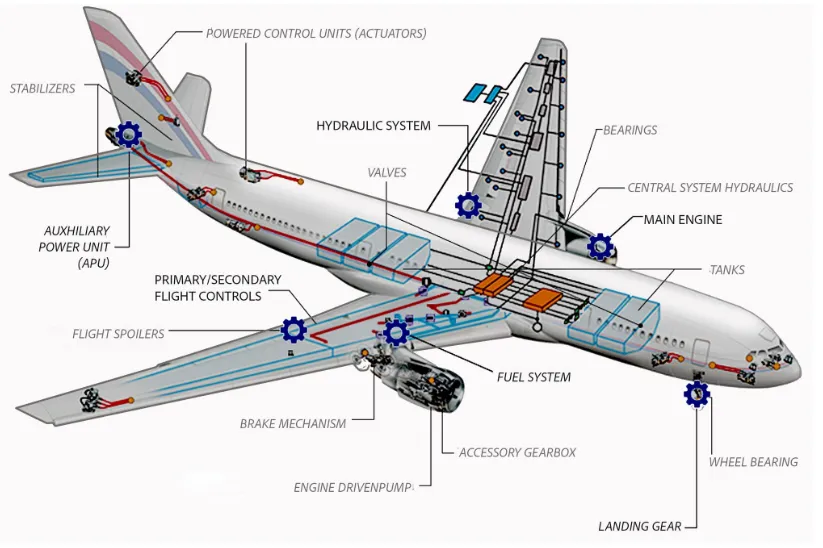

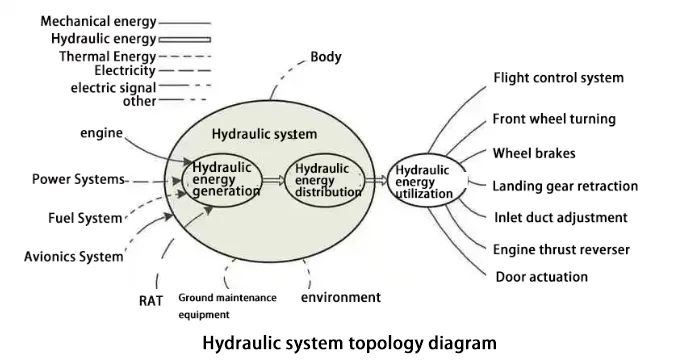

The hydraulic system is an electromechanical system that obtains energy from on-board or off-board sources (engines, motors, APUs, EPUs, RATs, etc.), converts the obtained energy into hydraulic energy, regulates and distributes the hydraulic energy, and transmits it to the various types of hydraulic actuators on the airplane. These actuators include flight control actuation, forward wheel turning, wheel brakes, and other systems that require hydraulic energy for motion conversion or servo manipulation, and the topology formed by the hydraulic system and the internal and external systems/environments of the aircraft.

The hydraulic system plays a vital role in ensuring the safe and normal flight of the aircraft, accomplishing the design performance as well as guaranteeing flight safety. With the unremitting pursuit of safety and power-to-weight (mass) ratio (referred to as power-to-weight ratio) of civil aircraft, and under the traction of multi-electrification, additive manufacturing, and other technologies, the development of hydraulic system of civil aircraft in recent years has presented some new features.

I. Development History

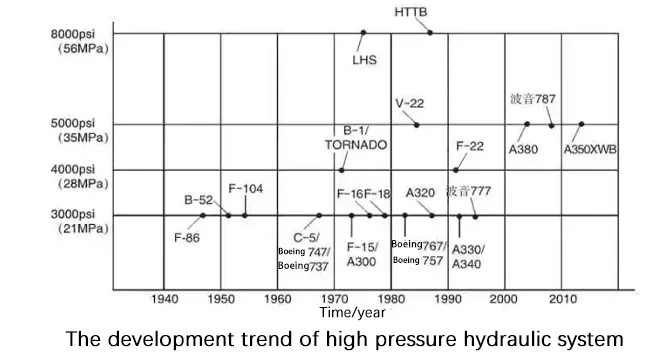

Hydraulic systems appeared in airplanes as early as the 1930s to drive retractable landing gear. Since then, the number of tasks performed by applying hydraulic power has increased, thus greatly increasing the power requirements and the pressure (compression) levels of the hydraulic systems, and it can be said that hydraulics play an important role in all modern civil aircraft.

The advent of hydraulically-assisted flight maneuvering systems was a landmark example of the application of hydraulic power, with the aid of which pilots were able to control rudder movements despite ever-increasing speed and maneuvering requirements. This application brought hydraulics into the realm of critical systems affecting flight safety, where a single failure could not be allowed to jeopardize flight safety. Considering the above reasons, the aircraft hydraulic system is designed into multiple sets of independent of each other margin system, and a single set of hydraulic systems and set up multiple hydraulic pumps to improve the reliability of the system.

Until now, the hydraulic system is still the most effective power source for the main and secondary flight maneuvering systems, landing gear retraction systems, and brake system of civil aircraft.

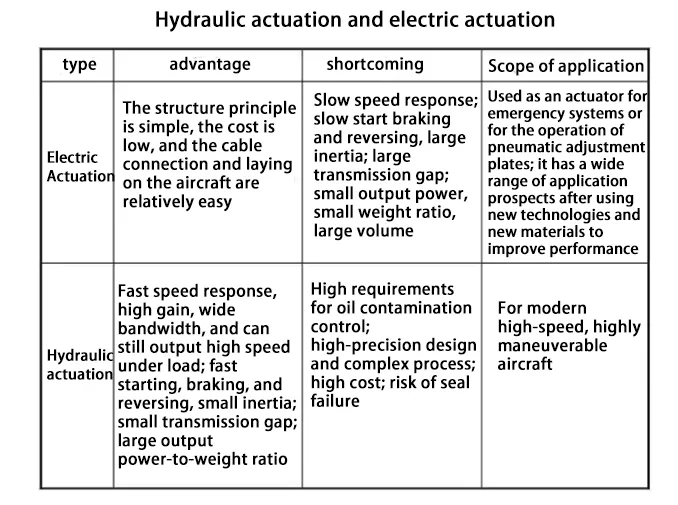

The application of hydraulics as a method of transmitting power has not been without its challenges from the outset. Of the various alternatives considered, the main competition came from the application of electrical systems. The rise of the all-electric/multi-electric aircraft concept has led to the emergence of electric actuation systems based on power electrical transmission as a research hotspot, and several technical papers have reviewed the advantages and disadvantages of both over the past 40 years or so. In comparison, it is found that hydraulic actuators are still the preferred solution for flight control actuation systems due to their relative stiffness, speed, self-lubrication of the actuator, and fault recovery. However, with the development of rare-earth permanent magnet materials, the power-to-weight ratio of the motor, the core component of the electric actuator, has been greatly improved, and it has been able to match the hydraulic actuator in small- and medium-power (3kW or less) actuation situations. In more high-power occasions, hydraulic and electric action combined with distributed hydraulic and action systems will become the future direction of development.

On the other hand, the rapid development of analog and digital technologies has led to the rapid progress of hydraulic systems in monitoring and executive control functions. New technologies such as hydraulic system failure prediction and health management, and intelligent variable pressure systems have been emphasized and researched, which can overcome certain shortcomings existing in the conventional hydraulic system and make the hydraulic system more powerful.

2. the development trend

(1) distributed

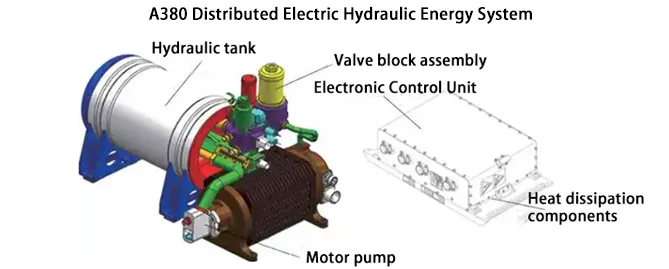

At present, most of the civil aircraft hydraulic systems use centralized oil sources, and engine-driven pumps to provide hydraulic energy for each user of the aircraft. Based on three or four sets of fault-tolerant designs the centralized hydraulic energy system has become the typical configuration of the hydraulic system of civil aircraft. With the development of large airliners, the shortcomings of centralized hydraulic systems appear to be non-negligible, and long pipes account for an increasing proportion of the total weight of the aircraft’s hydraulic system. An electro-hydraulic energy system can be arranged in the vicinity of the user, with its own control unit, not only to reduce the overall weight of the aircraft but also the distributed layout will greatly improve the reliability and maintainability of the aircraft. At present, the A380 is the first to use three sets of distributed electro-hydraulic energy systems as a backup hydraulic source for the front wheel turning system and the brake system.

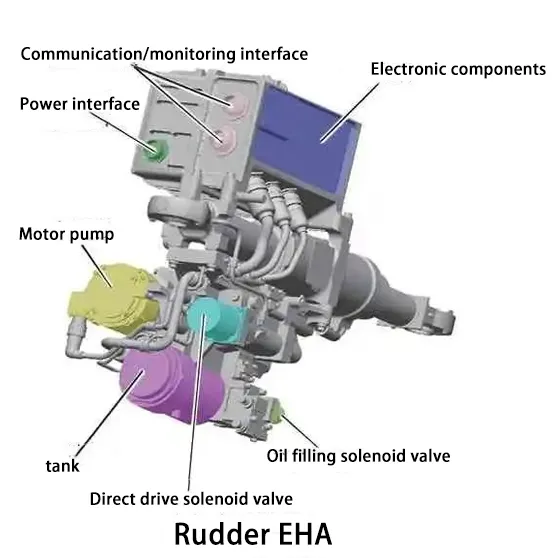

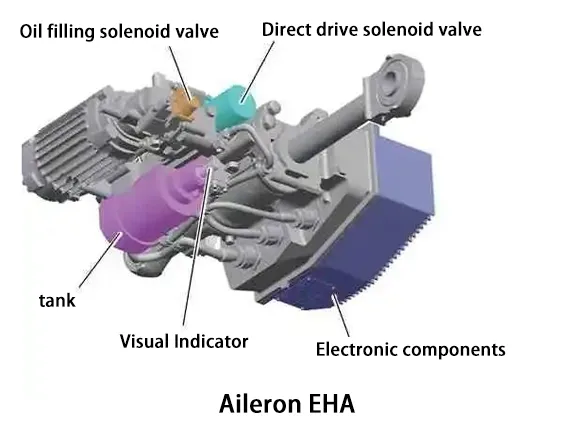

Further integration of distributed hydraulic energy with the terminal actuator results in the Electro hydrostatic Actuator (EHA), which, as an important part of the flight control system, is an important symbol of the technological advancement of the aircraft. A380 and A350 aircraft already in service have successfully canceled a set of centralized hydraulic systems by applying multi-electric technology and used electric actuator systems in more than 1/3 of the main flight control actuator system, mainly including EHA and electric backup hydraulic servo actuator (EBHA, the core technology is the same as EHA). The use of EHA as a typical representative of the electric actuator system enables the aircraft to obtain more benefits, mainly in the following three aspects:

①Reduce a set of hydraulic systems, reduce the weight of the aircraft, such as the A380 using 5000psi (1lbf/in2 = 6.895kPa) hydraulic pressure system and EHA/EBHA technology to reduce the weight of about 1t.

② power transmission using a certain degree of flexibility of the cable instead of rigid hydraulic piping, so that the aircraft on-board equipment layout and overall design with greater flexibility, power management, fault isolation, and fault-tolerant operation performance has been significantly improved.

③ The use of EHA/EBHA enhances the aircraft’s self-test capability, improves reliability, and also reduces the need for off-site maintenance, the maintenance equipment required, and the maintenance workload are greatly reduced, which is mainly due to the reduction of the replacement of hydraulic oil filters, adding hydraulic oil, inspection and replacement of piping and other regular maintenance work.

Airbus civil aircraft hydraulic system of electric drive development trend can be expected, in the field of civil aircraft, with the improvement of technological maturity, based on the centralized hydraulic system of the engine-driven pumps will gradually be electrically driven distributed hydraulic system instead.

(2)lightweight

Improves the power-to-weight ratio of the hydraulic system, and can increase the payload of the aircraft, research shows that: the hydraulic system weight reduction of 1kg, can reduce the aircraft structure weight reduction of 4kg, or increase the aircraft load carrying capacity by 15kg. therefore, the lightweight becomes the eternal pursuit of the development of the hydraulic system. At present, around the hydraulic system lightweight theme of research and application of hot spots is to improve the system pressure and the use of additive manufacturing technology.

①high-pressure hydraulic system

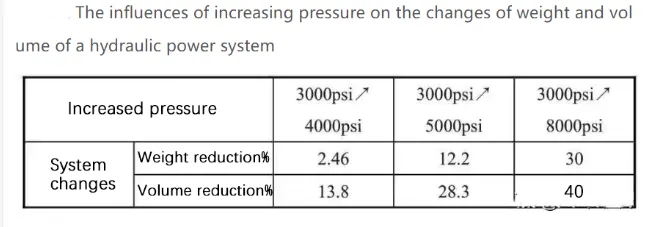

If the output power of the hydraulic system remains unchanged, that is, the product of the flow rate and pressure remains unchanged, according to the similarity criterion of the hydraulic system, the flow rate is proportional to the product of two-thirds of the volume of the hydraulic components and the flow rate. Increasing the pressure of the hydraulic system can reduce the flow demand, thereby reducing the volume and weight of hydraulic components.

Many foreign studies over the past 30 years have shown that: the most effective way to reduce the size and weight of the aircraft hydraulic system is to increase the working pressure. With 3000psi as the base pressure of the aircraft hydraulic system, considering a variety of design factors, without regard to the initial trial cost, the system weight of the smallest pressure is 4000psi; the use of steel or alloy steel material hydraulic system, the best pressure is 5000psi; the use of titanium alloy materials, the best hydraulic system, the optimal pressure is 8000psi.

At present, the 5000psi high-pressure level hydraulic system has become an important factor reflecting the technical level and competitiveness of civil aircraft and is the inevitable direction of the future development of civil aircraft. Aircraft hydraulic system pressure high-pressure development of this trend can be seen in the Boeing 787, Airbus A380, and A350XWB, and other large private aircraft use 5000psi pressure level.

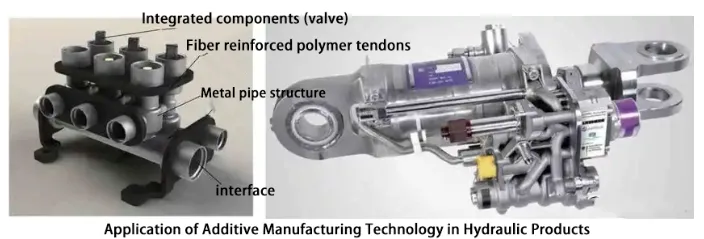

② Additive manufacturing technology

High-performance metal components additive manufacturing technology is based on metal powder as raw material, through the high-energy laser layer-by-layer melting deposition growth (additive manufacturing), directly from the digital model of the part in one step to achieve a large and complex whole high-performance metal components of the “near-final forming”. Additive manufacturing technology applied to civil aircraft hydraulic systems in complex hydraulic products, through flow channel optimization, topology optimization, and process optimization, can significantly reduce the weight of hydraulic products. The German Liebherr company, for example, uses additive manufacturing technology, so that the A380 hydraulic actuator weight is reduced by 35%, and volume reduction by 15%, while the number of product parts is also reduced by 15%. The main components of the hydraulic system hydraulic pumps, hydraulic tanks, hydraulic pressure accumulators, and hydraulic actuators have a similar design method, additive manufacturing technology can be used as a means of reducing the weight of the hydraulic system components, to achieve the lightweight hydraulic system.

(3) intelligent

With the development of power electronics and computer technology, complex logic control methods are introduced into the hydraulic system standby pump start-stop control, according to the large flow and fault conditions, the timely start of the standby pump source, effectively reducing the pilot’s operating load, improve flight safety. At the same time, with the development of sensor technology, the system state parameters and health monitoring are also constantly improved, the system’s oil volume, pressure, and other states, as well as overheating, low-pressure, and other failures, can be visually displayed in the cockpit, which will help pilots to understand the status of the aircraft in a timely manner and make a response, but also as a system of automatic control and fault reconstruction of the input conditions. Therefore, the aircraft hydraulic system is gradually becoming intelligent.

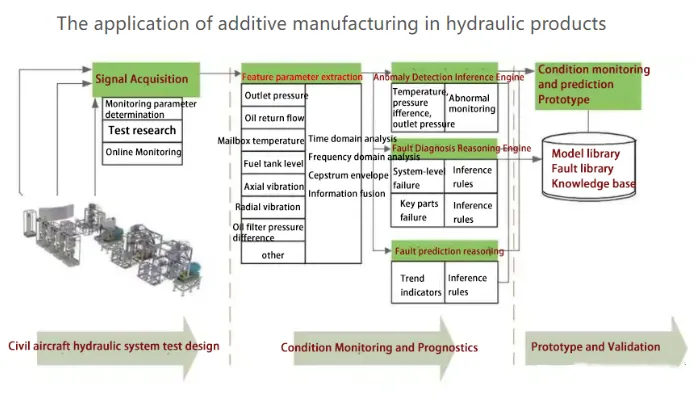

① Fault prediction and health management

With the continuous promotion of failure prediction and Prognostics and Health Management (PHM) technology in civil aircraft, as well as the improvement of aircraft electromechanical system monitoring technology and capability, the research foundation of hydraulic system condition monitoring and prediction technology for civil aircraft has matured. The improvement of hydraulic system condition monitoring and prediction capability can not only warn the hydraulic system before failure to avoid the serious consequences that may be caused by the occurrence of the failure but also can reasonably and flexibly arrange the maintenance tasks through the life prediction to improve the utilization rate and economy of civil aircraft。

The research of PHM technology for the hydraulic system of civil aircraft needs to break through a number of key technologies, such as top-level design and demand analysis of the hydraulic system PHM, hydraulic system failure mode analysis and monitoring layout, online monitoring of oil and fluid, and diagnosis and prediction of failure of the hydraulic system and key components.

② Variable pressure control

Increasing the pressure of the hydraulic system will bring a series of benefits, but with the increase in pressure and power of the hydraulic system, heat generation, component wear, and tear also increase, thus reducing the heat generation of the hydraulic system, improving energy efficiency has become the main problem to be solved. Variable pressure hydraulic system is a system that uses hydraulic power on demand, with the advantages of energy saving and reducing heat generation, and the system weight is also effectively reduced. This variable pressure is realized by its own sensing information and control algorithms and is already characterized by intelligence.

Japan’s Fuji Heavy Industries, Inc. has conducted a lot of research on aircraft variable pressure maneuvering, and they have conducted statistics on the pressure and flow of large and small aircraft in flight, and the results show that the aircraft in flight in a high-pressure or high-flow state is a very short period. Maximum pressure is only needed for certain short flight states in the aircraft flight, such as takeoff, landing, etc., which account for about 10% of the flight time, and the low pressure can ensure all the needs of aircraft control in the rest of the flight states (90% of the flight time). After a comparative study, the power consumption of the variable pressure system is much smaller than that of the constant pressure system, and the temperature rise is also much smaller.

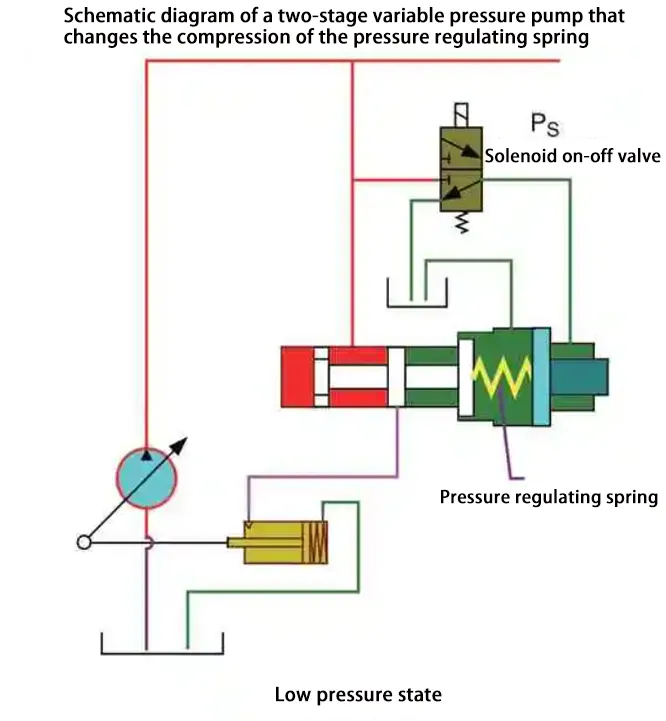

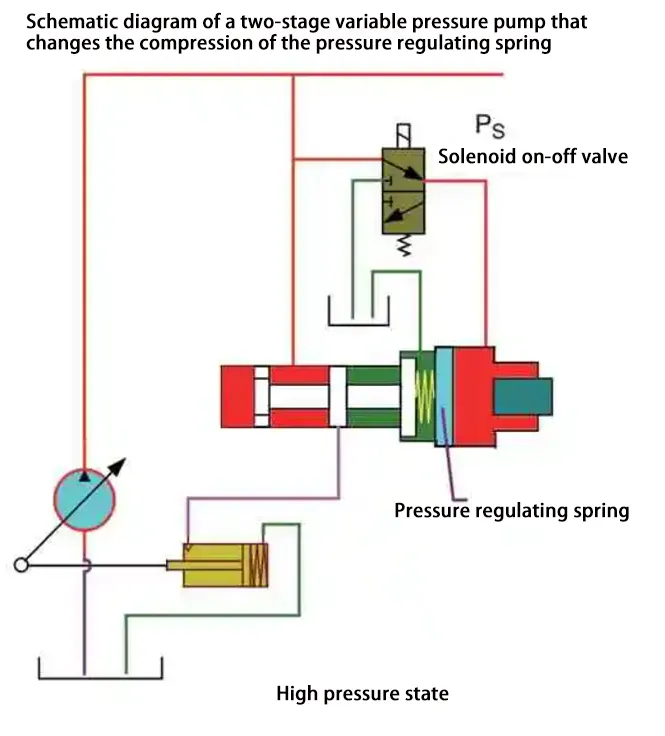

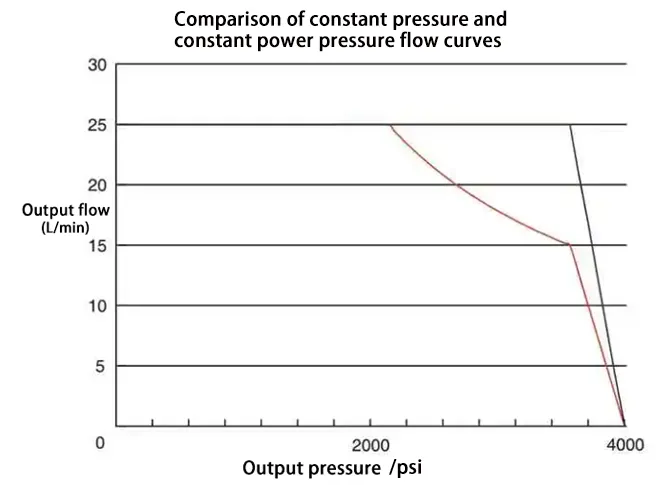

From the current research progress at home and abroad, variable pressure can generally be divided into two types of double-stage variable pressure and step-less pressure regulation, because the main hydraulic system hydraulic pump generally provides pressure for multiple users, each user’s demand for pressure is inconsistent, the use of more reliable double-stage variable pressure is more practical. Based on the principle of two-stage variable pressure variable pump to change the compression of the regulator spring, when the electromagnetic cut-off valve is energized, the mounting seat of the regulator spring is in the right position under the action of the spring force, the pre-compression force of the regulator spring is small, and the system is balanced in a low-pressure state under the action of the regulator, and in the opposite case, the electromagnetic cut-off valve is energized, the pre-compression force of the regulator spring becomes larger, and the system is in a high-pressure working state.

Another typical application scenario of variable pressure control is the energy supply of the brake system. Since the transient flow demand of the anti-skid brakes is very large, a pressure accumulator is generally used as a hydraulic energy regulator to supplement the transient flow and prevent the sudden change of pressure from affecting the rest of the system. When using distributed hydraulic energy to supply pressure for the brake system, the use of constant power-based pressure and flow intelligent regulation schemes has more obvious advantages.

The characteristics of the constant power control scheme are to increase the flow output without increasing the motor power; and to meet the high flow demand of the anti-skid brakes by reasonably setting the constant power point. In the same motor peak torque conditions, the use of this constant power control pump can give full play to and utilize the energy of the motor, which in turn can reduce the motor power requirements. With reduced motor power, the volume and weight are reduced accordingly, giving a greater advantage in terms of power-to-weight ratio. Currently, this form of control has been adopted for the backup distributed hydraulic energy source of the A380 brake system, which saves about half of the extracted electric power compared to a constant pressure variable oil source.

3. Conclusion

As the country becomes increasingly prosperous and the people’s living standards continue to improve, the demand for convenient travel is becoming stronger and stronger, and civil aviation has also ushered in the best development opportunities. As the power source for various aircraft control devices, hydraulic systems are still the preferred solution for various newly designed civil aircraft, and are gradually developing in the direction of decentralization, lightweight and intelligence. Grasping the latest progress of civil aircraft hydraulic systems can point out the research direction of related technologies and improve the performance of civil aircraft hydraulic systems, which is of great significance to improving the design and manufacturing level of our country’s civil aircraft.