Correct installation of hydraulic hoses is extremely important. Most hose failures are caused by improper installation of the hose assembly on the hydraulic system.

1. Hydraulic pipeline layout basics

In the hydraulic system, the fixed layout is connected by steel pipes, and the layout between the movable parts is connected by hoses. If the cost and appearance are not much different, especially when there is vibration, try to use hose layout.

2. Hydraulic hose installation specifications

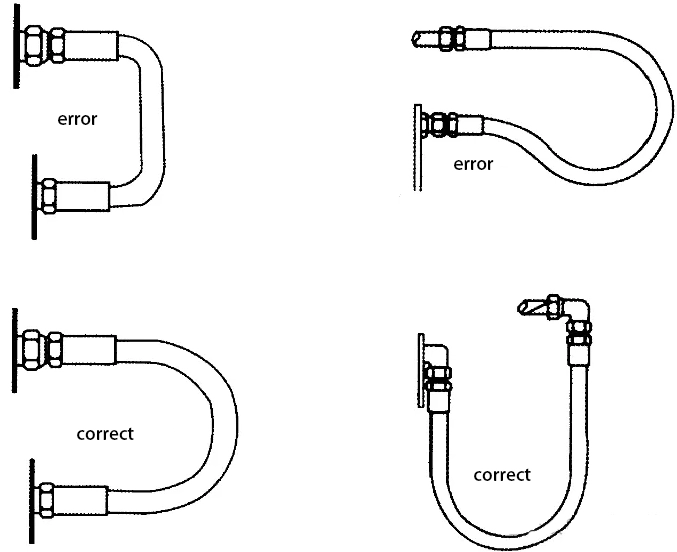

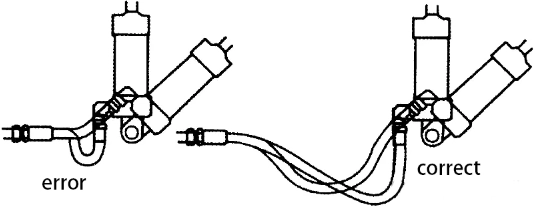

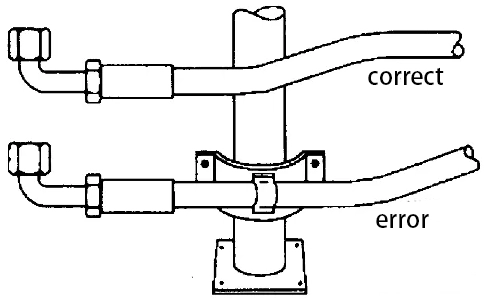

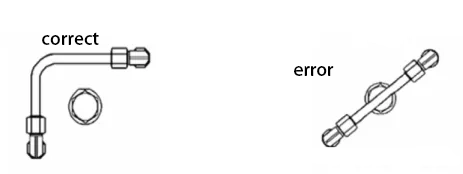

(1)Twisting the product will significantly shorten its life and may easily damage the hose or loosen the connection when under pressure. According to the test, the service life of the hose can be reduced by 80% by twisting just 7°.

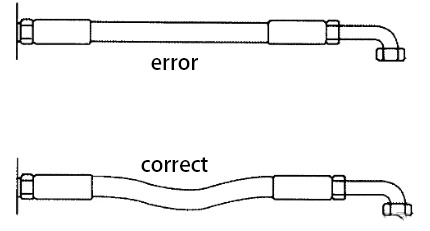

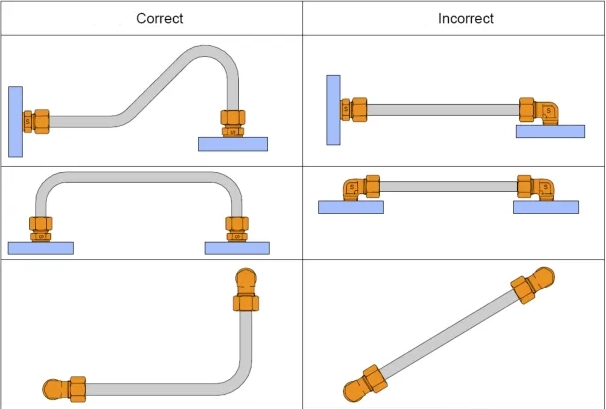

(2)When installing a straight pipe, a margin should be reserved so that it will not be tightened or even broken when it moves under pressure. Under pressure changes, the house will expand and contract to a certain extent, so a margin of about 3% to 5% must be reserved.

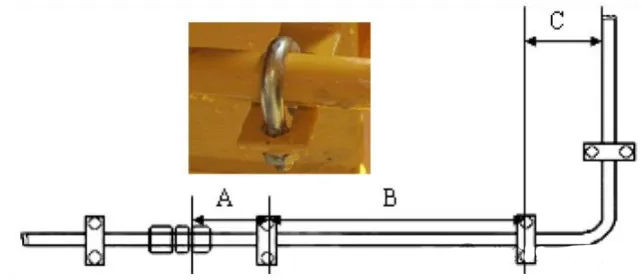

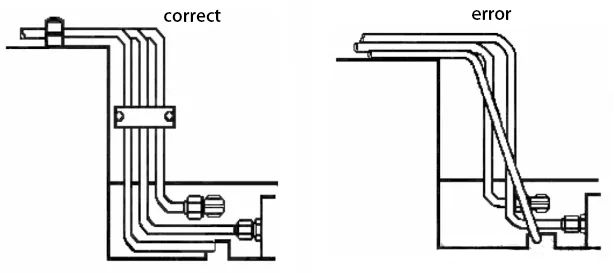

(3)The pipe clamp is on the straight section. When the hose is under pressure, the pressure inside and outside the bend is unbalanced, and the length of the pipe will change. Therefore, the pipe clamp cannot be set at the bend to allow it to move freely.

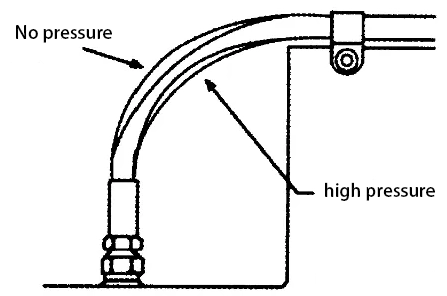

(4) Meet the bending radius requirements. A bending radius that is too small will tear the reinforced wire braid on the outside of the bent part of the hose, significantly shortening the life of the product.

(5) Sports adaptability. Sufficient length should be reserved to ensure that it has a certain degree of sports adaptability and avoid friction with other objects.

(6) Heat insulation or adding sheaths and pipe clamps to avoid friction. Sufficient length should be reserved and friction with other objects should be avoided.

3. Hydraulic hard pipe installation specifications

(1) When installing hydraulic hard pipes, the pipe length should not be too long, and the pipe diameter should be appropriate. Excessive flow rate will cause energy loss.

(2) It will not cause severe tensile stress due to thermal expansion and contraction.

(3) The minimum bending radius of the rigid pipe should be at least 2.5 times the diameter. A straight section should be left at the end of the pipe, and its distance should be more than twice the height of the pipe fitting nut. At the same time, it should be ensured that there is enough straight section for clamping when the rigid pipe is bent.

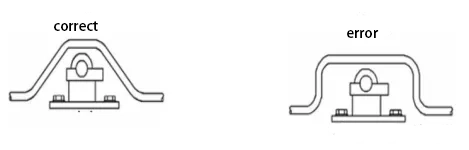

(4) When the rigid pipe is long, it needs to be supported by a pipe clamp, which can not only buffer vibration but also reduce noise. The straight sections at both ends of the curved pipe should be fixed with a supporting pipe clamp. When connecting with a hose, a pipe clamp should be added to the rigid pipe end for support. The pipe clamp should be an adjustable anti-loosening type.

(5)Do not use too many 90° bent steel pipes to avoid obstacles. The pressure drop of the fluid passing through a 90° bent pipe is greater than that passing through two 45° bent pipes.

(6) When laying out pipelines, try to keep them away from areas that require frequent maintenance.

(7) When laying out pipelines, the rigid pipes must be arranged in an orderly and neat manner to facilitate fault detection, maintenance and repair.

(8) Rigid pipes must not be placed in the air, and anti-vibration and fixing measures should be taken.