1. Gear reducer

Type: cylindrical gear reducer, bevel gear reducer, helical gear reducer, etc.

Features:

High transmission efficiency (90%-98%), suitable for high-power scenarios. Strong load-bearing capacity, suitable for heavy-duty industrial equipment (such as mining machinery, metallurgical equipment) with compact structure, but some types (such as spur gears) have high noise. Transmission ratio range: Single-stage transmission ratio is usually ≤5, and multi-stage combinations can reach higher.

2. Planetary reducer

Structure: It is composed of sun gear, planetary gear and inner ring gear.

The characteristics are high precision (small backlash), suitable for precision machinery (such as robot joints, CNC machine tools).

Small size, high power density, and better load-bearing capacity than ordinary gear reducers at the same volume.

Wide transmission ratio range (3-1000), multi-stage series expansion.

High cost and complex manufacturing process.

3. Worm gear reducer

Structure: Worm (helical) drives worm wheel (gear)

The characteristics are large single-stage transmission ratio (10-100) and compact structure.

Self-locking function (reverse transmission is difficult), suitable for scenes with high safety requirements (such as elevators).

Low transmission efficiency (40-85%) and high heat generation.

Medium load-bearing capacity, suitable for small and medium power equipment.

4. Cycloidal pinwheel reducer (RV reducer)

Structure: Based on the cycloidal pinwheel meshing principle.

Features are high rigidity, high precision, and extremely small backlash (≤1 arc minute).

Strong impact resistance, suitable for industrial robots and precision turntables.

Wide transmission ratio range (30-300) and high efficiency (80%-90%).

High cost and difficult to manufacture.

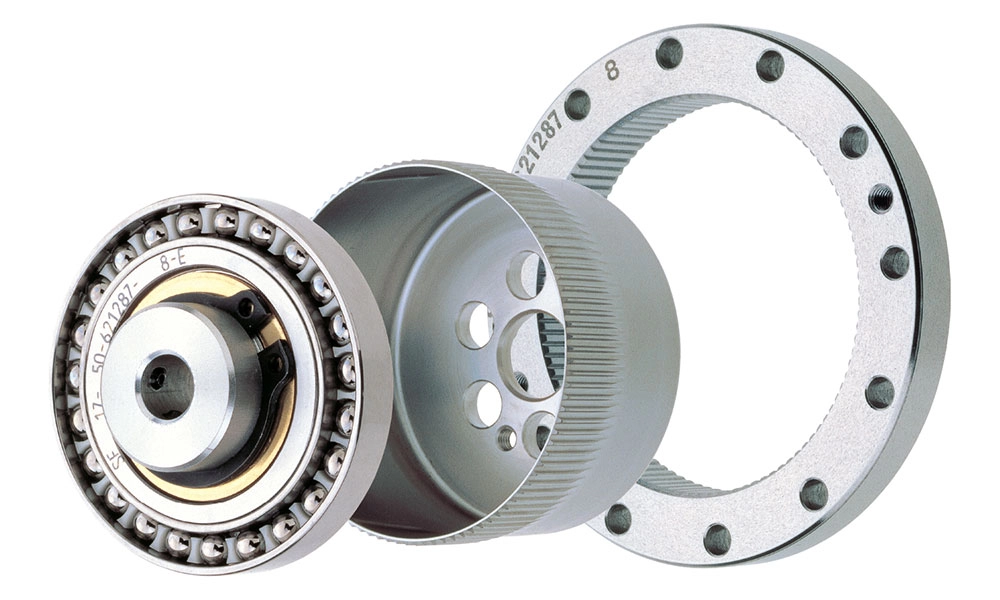

5. Harmonic reducer

Structure: It consists of a flexible wheel, a rigid wheel, and a wave generator.

The characteristics are small size and light weight, suitable for lightweight equipment (such as collaborative robots).

The transmission accuracy is extremely high (backlash ≤ 0.1 arc minute) and the repeatability is good.

The transmission ratio range is (50-160), but the load capacity is low. The flexible wheel is prone to fatigue, and its life is affected by load and speed.

6. Parallel shaft reducer

Structure: The input shaft and the output shaft are arranged in parallel.

Features:

The characteristic is that it is easy to install and is suitable for conveyors and packaging machinery. The transmission efficiency is high (90%-95%), but the volume is relatively large.