In the field of mechanics, there are many widely adopted mechanical structures, but for newcomers to this field, these classic mechanical structures may still be unfamiliar. This article aims to lead you to a deeper understanding of several popular mechanical devices.

1. Linear guide and linear motion assembly

An example is a linear motion mechanism composed of a linear guide shaft and a linear motion assembly. By using a shaft with an embedded part, it is easier to ensure the accuracy (i.e. coaxiality) during assembly.

The shaft is inserted into the hole on the connecting plate, and the coaxiality of the guide shaft is determined by the position accuracy of the hole. The core components are the guide shaft and the linear motion assembly.

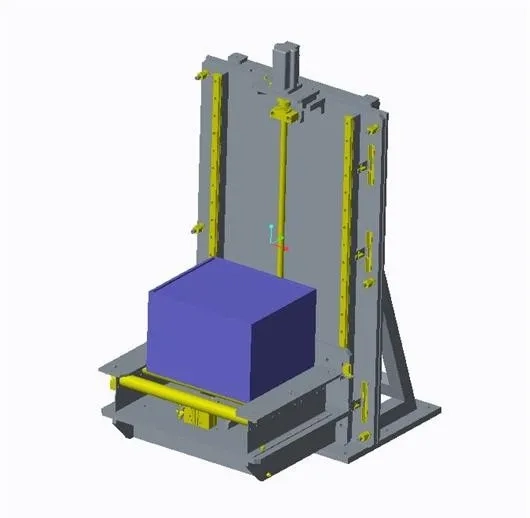

2. Vertical lift

This is an example of using a flanged linear motion assembly to achieve up and down movement. Because a flanged linear motion assembly is used, no additional bearing seat is required.

Note the floating connection design between the cylinder piston rod and the dowel pin mounting plate. The core components are the guide shaft, linear motion assembly and cylinder.

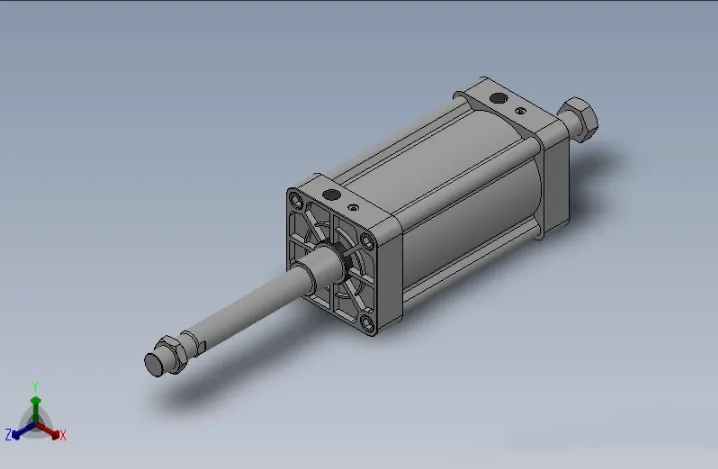

3. Cylinder stroke adjustment device

This is an example of using a retaining ring to adjust the stroke of a dual-axis cylinder. Fine adjustment can be easily achieved by rotating the screw on the inner diameter.

The inner hole of the retaining ring is a threaded hole for easy position adjustment, and the open screw fastening structure is used to fix the retaining ring. The core components are the retaining ring and the cylinder.

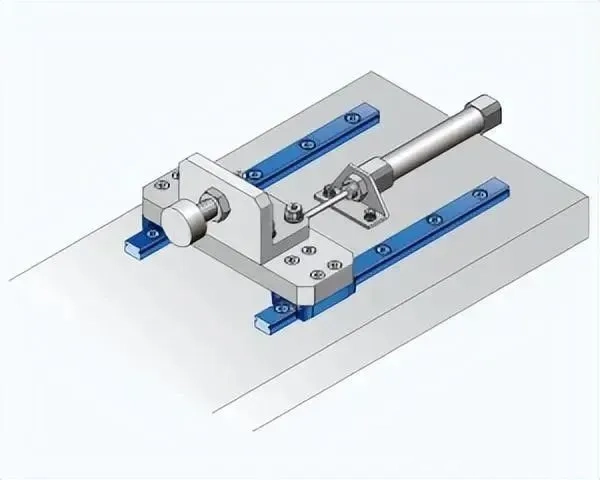

4. Linear propulsion system

This is an example of a propulsion system using linear guides and cylinders. Choosing a miniaturized design can greatly reduce the overall height.

Please ensure that the cylinder piston rod and the moving block are connected in a floating manner; if the guide accuracy requirement is not high, a single guide rail can be used instead of a double guide rail, or a single guide rail double slider structure can be used to improve stability. The core components are miniature linear guides and cylinders,

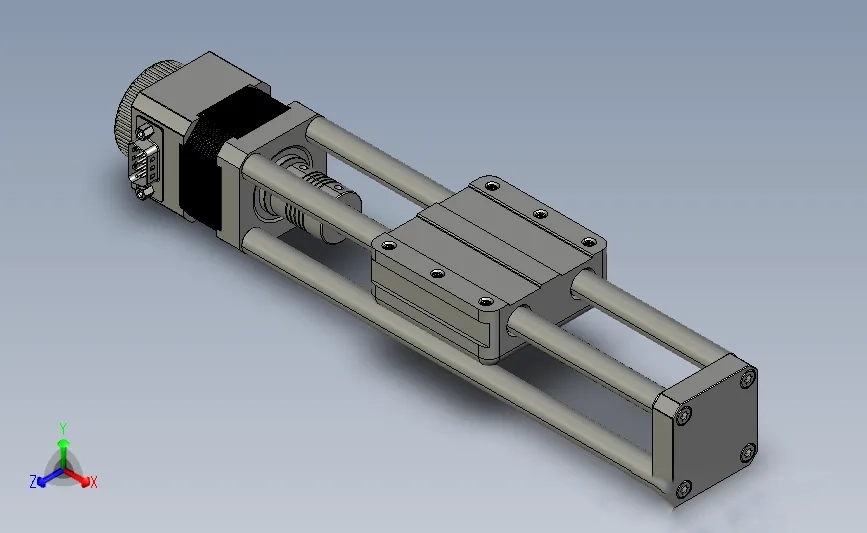

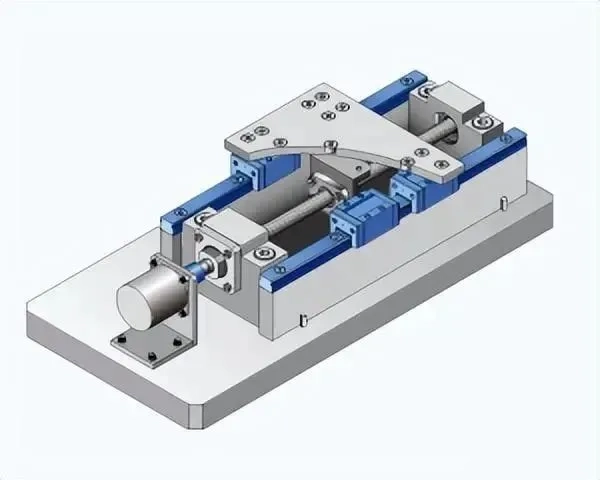

5. Ball screw linear motion mechanism

This is an example of a linear motion mechanism composed of a linear guide and a ball screw. In order to ensure the space for the ball screw, a gasket needs to be installed on the guide rail.

To ensure the parallelism of the two guide rails and the ball screw, it can be achieved by optimizing the structural design and improving the processing accuracy; after the moving plate and the slider are locked, when the nut is locked, in order to reduce the resistance, in addition to the gasket adjustment method, the pin connection method can also be considered to connect the nut and the moving plate into a floating structure. The core components are micro linear guides, couplings and servo motors.

6. Simple vertical lifting mechanism

This is a simple linear motion mechanism driven by a guide rail composed of a shaft and an oil-free bushing. When precision guide rails are not required: more space can be saved.

Using this mechanism instead of a cylinder with a guide structure can reduce costs. However, please note that there is no floating connection between the cylinder lever and the moving plate here, so the accuracy requirement of the guide bearing should not be too high. The core components are the shaft and the oil-free bushing.